CT Scanner Equipment Gallery

| |

|

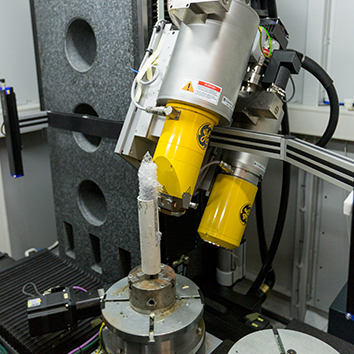

MicroCT: General Electric V|Tome|X L240 (up to 240 kV, down to 5 µm voxel size). Samples up to 250 mm in diameter.

|

|

MicroCT: sample loaded and showing the X-ray source in yellow

|

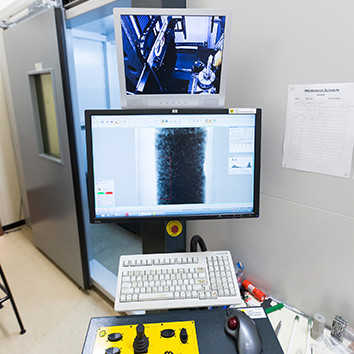

MicroCT: Settings selection done, X-ray image on screen with lead shielded cabinet in background. |

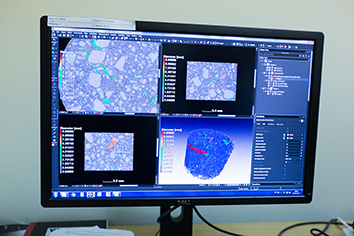

3D data analysis - using VGStudioMax 3.0. In this example concrete porosity is analysed providing 3D distribution and pore size analysis. 3D data analysis - using VGStudioMax 3.0. In this example concrete porosity is analysed providing 3D distribution and pore size analysis.

|  Data analysis facility: 3 workstations available for students to analyse their datasets, PCs can be booked in advance Data analysis facility: 3 workstations available for students to analyse their datasets, PCs can be booked in advance

|

The Industrial Computed Tomography (CT) Scanner is an x-ray inspection machine that allows 2D x-ray inspections of materials as well as 3D CT Scans of materials, to investigate and analyse the inside of any object non-destructively and at high resolution and contrast.

The measurement principle is similar to medical CAT scanners. An object is exposed to collimated x-rays and the absorbed radiation is measured with a sensor on the opposite side.

This procedure is repeated from different angles around the object which allows a full 3D recon-struction. The technique is used to detect small differences in density and atomic number of the scanned sample. CT scanning provides state of the art non-destructive analysis of material properties for a wide variety of materials. CT can be used to measure accurate distances, for example inside mechanical components, can be used to check porosity of materials, can be used to identify cracks, transitions or inclusions in materials, can be used to study the density variations within a sample, can be used to make a 3D CAD surface or volume data sets of the scanned object (eg. for reverse engineering). Standard 2D or 3D inspection reports are available, batch processing of large numbers of samples is possible, data can be provided in various formats such as jpg image slices, image stacks (this allows you to scroll through your object virtually in thin slices), dicom stacks (medical format), stl files (surfaces), or volume files (for self analysis of large volume data). Further analysis and high-end processing hardware and software is also available in our facility.

We provide an exciting new double-edged service where users can deposit their data for long-term storage (either entirely private or openly available to other users) and with all this data available we can also offer unique 3D datasets for sale. Our High Performance Centre makes available full time access to 3 dedicated analysis workstations with multiple CPUs, good graphics cards and 64 – 128 Gb RAM each, for advanced 3D data analysis. This is mainly for CT data analysis and we offer Volume Graphics VGStudioMax 2.2 & 3.0, imageJ and VSG Avizo Fire 9.0 & Simpleware but other softwares can also be installed, so please enquire about this.