The PRASA Chair continuously make use of the 'virtual laboratory' to perform laboratory research projects for PRASA, making use of the laboratories of the Mechanical Engineering and Industrial Engineering departments.

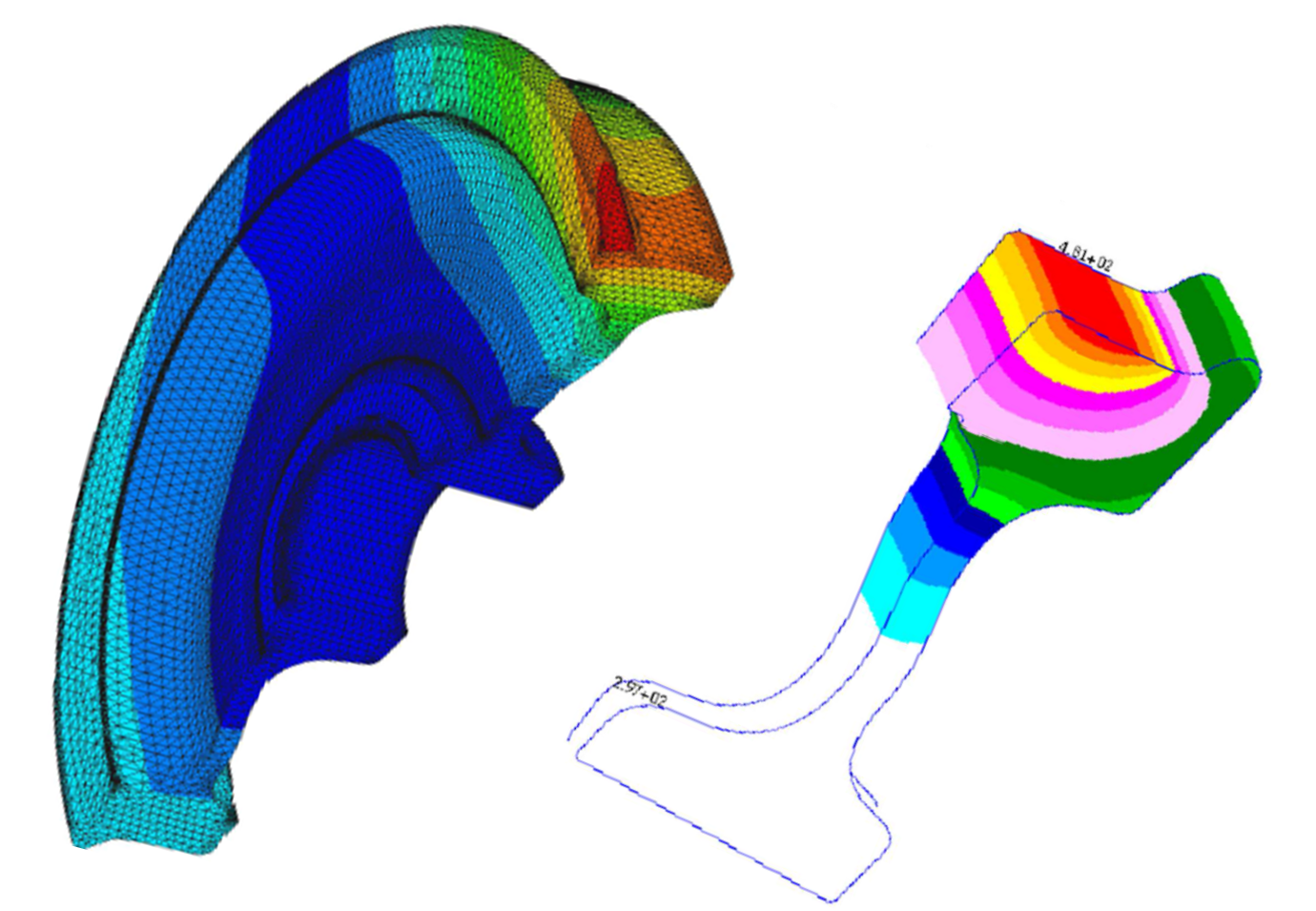

The PRASA Chair became a key player in the understanding of the rail-wheel interface, and conducted conformance tests on a variety of rail wheels and axles. These conformance tests included destructive and non-destructive conformance tests, in accordance with local and international standards, often using innovative methods during the tests, like using water jet cutting technology for cutting the wheel with no thermal input. By using computerised metrology, as described in more detail later, 3D models of the wheels and axles were generated through reverse engineering. These models were used for perform dimensional tolerance and other geometric tests on the wheels and axles, as well as static, thermal and fatigue Finite Element Analysis (FEA) on the wheels.

The standards were diligently followed during the tests and engineering reports created with recommendations.

The same 'virtual laboratory' was used for the conformance testing of different type of fasteners used in the rail track. The results were documented and presented to PRASA and recommendations were made in terms of the most suitable specifications to be used in future.

PRASA is busy with the mammoth task of converting railway drawings into a 3D format. While many components and assemblies are simple and a 3D model easy to create, many railway components and assemblies are complex and require more effort. With the Rapid Prototype Development (RPD) department, part of the Industrial Engineering department, the PRASA Chair has access to specialised equipment to create accurate 3D components, such as the GOM (Gesellschaft fur Optische Messtechnik) 3D digitising equipment. Calibrated digitising cameras are used to collect coordinates from thousands of points on the surface of a component, which is then used to create an accurate FEA-ready 3D model.

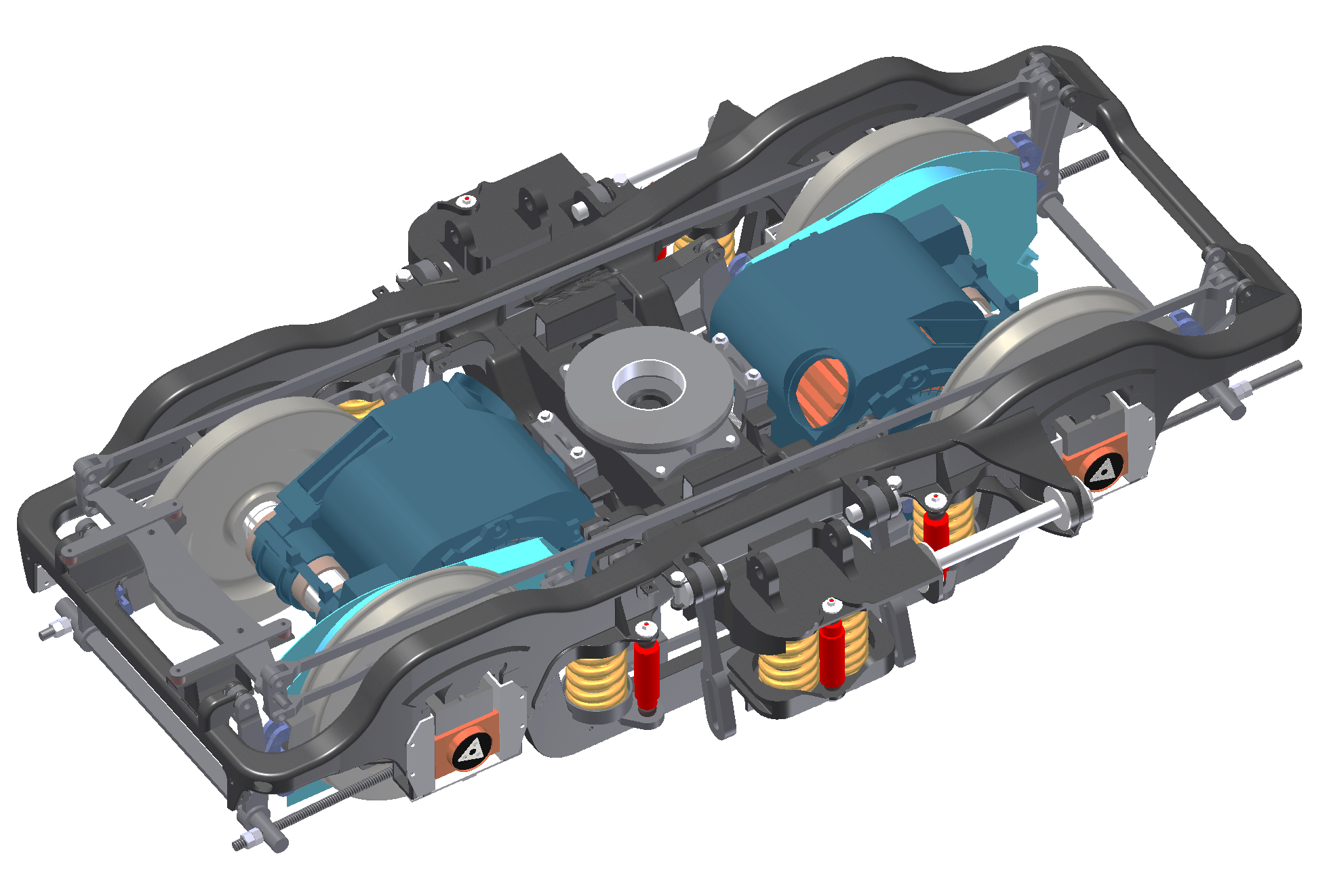

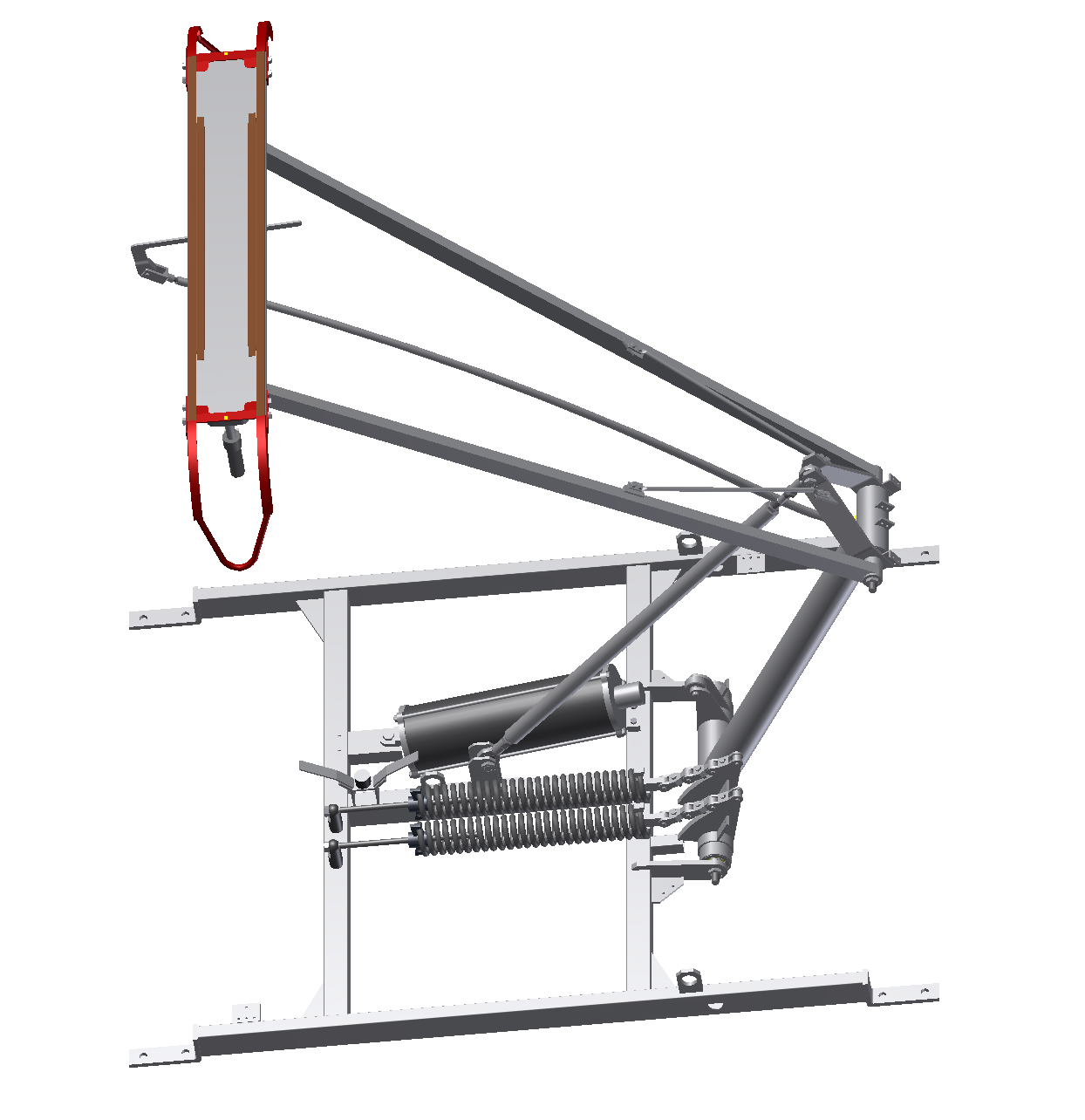

Using these equipment, various 3D models were created, such as the undercarriage of the 5M Motor Coach, 5M wheel set, 8M wheel set and the pantograph assembly.